The preparation and use of metal materials has been one of the largest and most important materials we have ever used to build and change the world. However, perfection is difficult to reach, the strength and toughness of metal materials often cannot be both. So since the beginning of cold weapons manufacturing thousands of years ago, people have been looking for strong and tough metal materials, and since then, people have realized that the different processes of metal materials must be changing something, because it will bring about significant changes in toughness. As our ability to recognize the world increases, we already know that this what is the structure of the material. The so-called “thousands of hammers”, this change in the structure to better performance of the nature of the relationship.

In recent years, this long-standing field of metal structural materials has been stirred up by a wave. It has been found that if traditional alloy design methods (a small number of alloy elements are added to the main element) and a number of elements and other atoms are dissolved together, the so-called high entropy alloys, which are theoretically arranged in an orderly and disorderly manner, could theoretically be made. Some high entropy alloys can have both high strength and high plasticity, thus breaking the difficult dilemma of strong plasticity in traditional metals. But the reasons behind it are elusive. For the study of high entropy alloy structure-performance correlation, there is a great “Lushan” state.

Recently, Yu Qian of Zhang Ze's team and Zhu Ting of georgia Institute of Technology in the United States, and Robert. Ritchie collaborated to uncover the true face of Lushan by decrypting the distribution of elements in high entropy alloys. “An accurate understanding of the causes behind the high-strength plasticity in high-entropy alloys will help us uncover efficient toughening mechanisms that facilitate material performance optimization design and research and development of high-performance alloys,” Yu said.

The results were published online in Nature, the world's leading magazine, on Oct. 10, Beijing time. The first unit of the thesis is Zhejiang University, the first author is Dr. Ding Qingqing of Zhejiang University's Institute of Materials Science and Engineering, Dr. Chen Xiao of Tsinghua University, Georgia Tech Ying Zhang is the co-first author, the communication author is Professor Yu Wei of the Electronic Microscope Center, Professor Ting Zhu of Georgia Tech, professor Robert Ritchie of the University of California, Berkeley is the co-author of the communication.

(Paper link: https://www.nature.com/articles/s41586-019-1617-1)

How hard steel just turned into a soft around the finger

What is a high entropy alloy? This is a crystal structure formed by the high concentration of a variety of elements solid together and the element distribution is chaotic solid solution, one of the typical high entropy alloy Cantor alloy composed of iron, cobalt, nickel, chromium and manganese elements. Since the performance is determined by the structure, the lattice is also the nature control unit of defective structure and behavior such as dislocation and decrypting the correlation between the base-sequence-performance in the high-entropy alloy is the key. However, iron, cobalt, nickel, chromium, and manganese are all close neighbors, electronegative, atomic radius, atomic number, and other differences are not large, from the lattice scale directly to analyze the deformation of high-entropy alloys is very difficult.

As one of the most important crystal defects, the dislocation structure, when the dislocation starts, how to slip and interact after starting directly affect the strength of the material and the ability to deform plasticly. From the point of view of dislocation theory, the structure and behavior of dislocation are directly affected by the lattic grid of atomic scale, especially the arrangement and distribution of various atoms. Yu said.

“Hills” ups and downs - dislocation slips are like cross tides and back tides

The residual group first revealed the important question of how various elements of high entropy alloys dissolve together by the distribution of elements at the atomic scale. We found unique concentration dislocation in high-entropy alloys, with concentrations of various elements fluctuating between 25% and 15% between lattiests in high-entropy alloys compared to elemental concentration dislocation that tend to be straightened at the lattic scale in traditional solid-solution alloys. Such dislocation in concentrations can lead to dislocation in nanoscale lattic resistance and changes in local layer error. Yu said. Then, by increasing the difference between electro-negative and atomic size between elements under the premise of ensuring complete solidity, Mr. Bei Hongbin prepared a CrFeCoNiPd alloy with nanoscale concentrations of various elements fluctuating between 60% and 0.

This is like a bunch of apples, pears, oranges, at first glance are similar, for a watermelon, it is very conspicuous, the manganese replaced with palladium, lattice regulation effect amplified, so that we 'see' the mechanism behind. Ding Qingqing said.

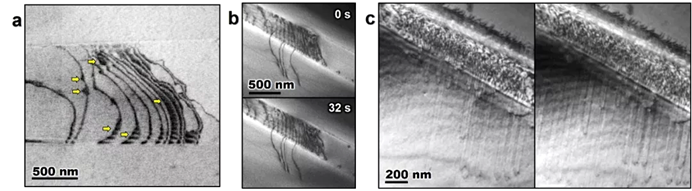

With the amplification of the high-fold mirror, the researchers saw that a dislocation, like a wave of money pond tide, rolled forward. The dislocation of ordinary material is to rush forward like a line of tide along a fixed sliding belt. But in the CrFeCoNiPd alloy, the dislocation stumbles. For example, the first-line tide that would have moved forward as a whole, like encountering a hilly, undulating bottom, changed direction and shape, forming a cross tide or even a back tide.

Large lattice resistance in CrFeCoNiPd alloys results in dislocation plugs when the dislocation slips through the FCC lattice

These “hills” are the dislocation in the concentration of different elements, and their existence is the essence of regulatory dislocation movement at the lattic scale.

The researchers called this dislocation movement cross-slip, and instead of walking along the original crystal surface, they chose another crystal surface. In this way, the interaction between dislocations increases, providing more possibilities for deformation, while also calling stronger external forces to push the dislocation forward.

“A lot of cross-slip makes the alloy have better uniform deformation and better strength, and fish and bear palms can have both.” Fu Xiaoqian, a member of the task force, said.

The dislocation middle of the CrFeCoNiPd alloy will result in high density cross-slip and secondary cross-slip

In ordinary materials, it is not common for such many violent cross-slips to occur.

Experiments have found that in CrFeCoNiPd alloys, the addition of palladium causes the dislocation in the concentration of all elements to increase. Due to the great increase in the amplitude of the concentration wave, the plastic deformation of the material at room temperature changes from the traditional dislocations slip, full-position slip, twin crystal deformation, etc. to the rare cross-slip of a large number of uniform distributions as the dominant deformation mode. At the same time, the change of stress distribution in the atom causes the lattic resistance shock of the very small spatial scale to increase significantly, and the geomorphology of the hills is created in the lattic, which is the essential reason for the emergence of a large number of cross-slips, and also makes the mechanical properties of the material compared with the CrMnFeCoNi alloy, in order to ensure a considerable level of plastic deformation capacity, the strength is significantly improved.

The study reveals the special mechanism of lattic regulatory properties in high entropy alloys, and compared with traditional interface regulation (including crystal boundary, phase boundary, second phase interface, etc.) and fine structure regulation such as clusters, the unique concentration wave regulation in high entropy alloy is very fine and continuous, which is a controllable and efficient method of material toughening. According to Nature's expert review, this work is of great theoretical significance for understanding the reinforcement of complex component alloys (traditional solid-soluble reinforcement theory is not applicable).

The characteristics of high entropy alloy strength and plasticity, as well as excellent low temperature performance, in the future aviation, the North and South Pole and other materials with strict temperature requirements can be prepared, at the same time in the field of collision prevention also has important applications.

This research is supported by the National Natural Science Foundation of China.

Text Reporter: Wu Yalan and Ke Yineng

Photojournalist: Lu Shaoqing. Some of pictures were provided by the task force

Camera reporter: Wang Xiaoyong

GIF Productions, Today Editor: Jia Le

Responsible Editor: Jin Yunyun